SHUT DOWNS

We have done several weekend shutdowns for various companies. Companies tend to prefer us to do their shutdowns because we have the hardest working team you will ever meet. Our forte is delivering quality work in a timely manner.

Almost every month we are working on a shutdown for a company. Whether it is a 2-day shutdown or a 2-week shutdown, we make it happen.

Here are a few examples of weekend shutdowns we have done.

One shut-down we added an additional air compressor and all the tie-in piping.

Another shutdown, we ensured all the pressure vessels were in top shape by doing a pressure vessel cleanout, inspection, and repair.

On an additional weekend, we installed new process piping that included insulation and heat trace.

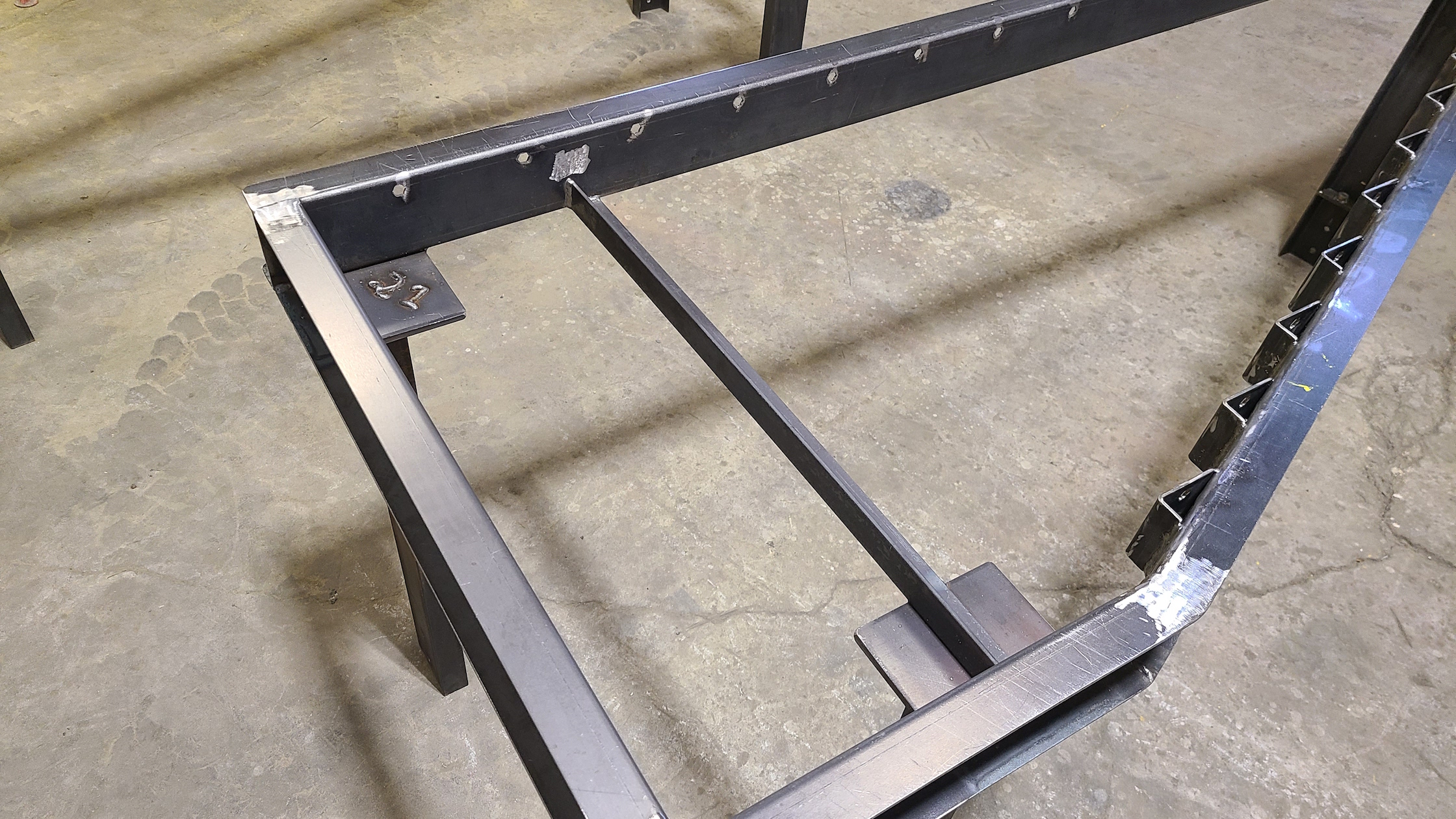

We always complete our job within the timeframe we bid, even if we only have 2 days to complete it. The way we make this possible is by coming in a week or two before the shutdown and doing all of the prep work beforehand. We fabricate all materials needed in our shop prior to the actual shutdown, including spooling pipe.

At least a day before the shutdown we have all materials waiting at the job site.

Then our workers take shifts working around the clock to install equipment, piping, steel, and all the tie-ins in a matter of days.

We are professional at minimizing downtime.

PROJECT GALLERY